If end laps are required you should allow 300mm minimum overlap sealed with butyl sealant tape 10mm from the edge of each overlapping sheet as well as in the middle of the overlap.

Overlapping steel roofing lengths.

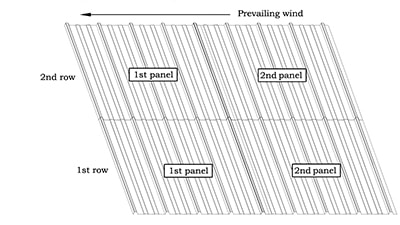

Once the first sheet is in place you need to install the remainder of the lowest row of corrugated metal roofing.

Roofing panels come in many styles and dimensions with different overlap dimensions.

The most common widths are 24 and 36 exposed but the actual width of the panel will be larger to accommodate an overlap.

Install the roofing screws vertically along each rib in the panel.

The easy installation involves placing metal panels on your roof but you ll need to be mindful of metal roof overlap.

This will void your paint system warranty as no.

Metal roofs though less appealing than shingle or tile is a more fire resistant and heat reflecting roofing option.

Lay the remainder of the row.

Sheet lengths of up to 24m can be used before an expansion joint is required for roof applications.

We recommend about 2.

Be sure the larger edge is laid so that the small edge of the next panel will overlap it.

On the eave side of the roof aim to overhang the panels by 1 to 1 5 inches.

How to cut metal roofing never use a circular saw or other device that will fling hot metal chips all around the area you cut.

The most common lengths are 8 10 12 and 16 however many distributors will cut to length.

If your panels aren t layered properly water damage can occur.

Sheets are supplied custom cut.

Any end laps must be supported by a suitable purlin.

Overlapping anti condensation lined sheets.

Make sure the panel is square to the roof line.

If you re installing a metal roof on a home without gutters you can overhang the panels by twice that amount.

The metal roof length calculator calculates the distance from peak to trim so add the length you want the roof metal to extend beyond the eave trim.